Main Features Overview

All-in-One Technology

All-in-One units are the first in powder coating industry that merge electrostatics and powder feed technology in one very compact device.

DualSpeeder: Handle two colors in parallel

Operation with two OptiSpeeder powder hoppers (DualSpeeder) allows handling and preparation of two independent colors sequentially for ultra-fast color change or in parallel for simultaneous coating from both OptiSpeeder hoppers.

OptiSpray All-in-One: Dense phase powder delivery and charging technology in one device

Best coating results and fastest response times

Any powder, any color, any time

Operation with two independent OptiSpeeders (DualSpeeder) allows different coating modes, such as separated coating with fresh and recovery powder or operating as a dual fresh powder source.

MultiColor Switch

Thanks to MultiColor Switch technology, both powder hoppers can supply each gun in the system with powder.

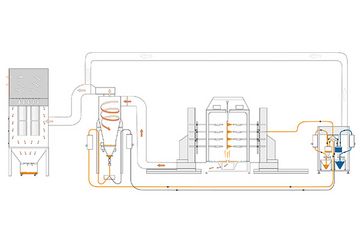

Closed loop and efficient powder circuit

The powder circuit guarantees a continuous and consistent powder feed with minimal wear and tear on components. The OptiCenter, application and powder pumps as well as recovery system are all ideally matched to each another and ensure perfect operating conditions.

OptiControl powder management control

The operation of the OptiCenter All-in-One is particularly intuitive and takes place via the 7” touch screen of the integrated OptiControl control unit.

Ultrasonic sieve insert US07

The free-swinging sieve surface ensures loss-free energy coupling for ultrasonic sieving and enables efficient sieving performance.

Fully integrated precision load cell weight detection

The fresh powder in the cone is weighed and processed in the batch management system of the MagicControl 4.0. This allows to easily record the fresh powder usage per batch, even during the replacement of a powder bag and monitor realtime information on the GemaConnect dashboard.

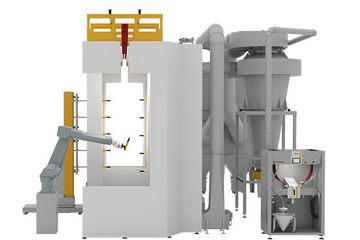

Compact design and flexible configuration

The OptiCenter All-in-One has a very compact design and can be flexibly adapted to any system layout, as no gun control cabinet is required.

Flexible use

The application possibilities of the OptiCenter are extremely diverse. Depending on requirements, it can be supplied as a stand-alone product or as an integrated component of a complete system with gun, axis and booth control.