Main Features Overview

Perfect powder conditioning and efficient color changes

The heart is the OptiSpeeder powder hopper, which optimally conditions the powder by fluidization. The new OptiSpeeder has a large inclined opening, which allows a quick and easy access and insight into the interior of the powder container.

Dust-free and clean working conditions

The closed powder circuit is controlled fully automatically and ensures a clean working environment as well as measurably higher efficiency.

Inline Injector OptiFlow IG07-PA for automatic coating

Ensures a constant powder flow, optimized color change and low operating costs with the most advanced injector technology.

Ultrasonic sieve insert US07

The free-swinging sieve surface ensures loss-free energy coupling for ultrasonic sieving and enables efficient sieving performance.

Individual cleaning efficiency

With the fully automatic cleaning of the powder hopper and all powder-carrying components, you achieve the highest cleaning efficiency! The user can apply the cleaning modes individually.

Fully integrated precision load cell weight detection

The fresh powder in the cone is weighed and processed in the batch management system of the MagicControl 4.0. This allows to easily record the fresh powder usage per batch, even during the replacement of a powder bag and monitor realtime information on the GemaConnect dashboard.

OptiStar® 4.0: The standard for gun controls

Control crucial coating parameters and obtain excellent results and measurable system optimizations with OptiStar. Access relevant coating data on your mobile device with the Electrostatic App.

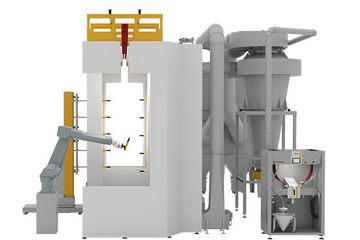

Flexible use

The application possibilities of the OptiCenter are extremely diverse. Depending on requirements, it can be supplied as a stand-alone product or as an integrated component of a complete system with gun, axis and booth control.