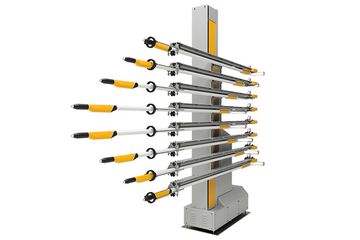

Stand-alone ZA10 vertical basic reciprocator

Perfect entry-level model for customers from different markets and various application demands.

ZA07/08/15 vertical reciprocator: powerful and reliable

Robust, reliable and easy to maintain reciprocators, with a high loading capacity, very precise movements and easy programming.

ZA16 vertical reciprocator: for complex application tasks

Extreme powerful reciprocator with space-saving design, very precise movements and easy programming.

ZA17 vertical module: for targeted positioning of the gun

The new vertical module in combination with the ZS05 stationary axis precisely positions the gun axis (UA05, UA05-x) on the coating object.

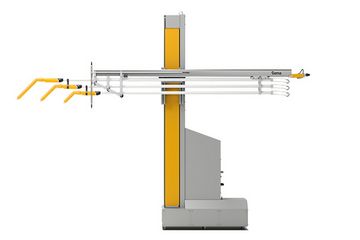

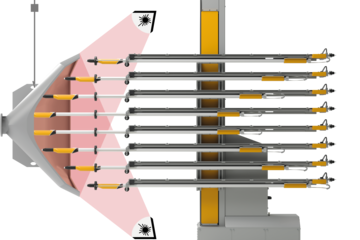

XT10/11/12 horizontal axis

The axis moves a ZA vertical reciprocator to the coating object, adjusting the gun position to the object width. The axis is also used to blowing off the guns during the color change.

YT05 synchronizing axis

The axis moves a ZA reciprocator synchronously with conveying motion of the objects and is used for inside coating and other difficult applications.

UA05 gun axis

Horizontal adjustment of the automatic guns allows optimum application position thanks to latest drive technology.

Multi-gun axis UA05-2, UA05-3

The solution uses a single positioning axis for the horizontal alignment of up to 3 automatic guns for top or underside coating of complex components and XXL parts.

SR tilting axis

SR axes tilt the axes and guns mounted on them from the orthogonal position to optimally coat parts in an inclined position.

AR rotating axis

This axis can turn 1 or 2 guns over a fixed radius. It is ideal to coat round shaped objects such as wheels or loading openings of washing machines.

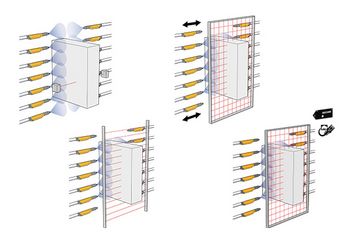

Part detection systems: quality and savings

Automatic guns positioning, triggering and setting improve finishing quality and reduce powder wasted in the recovery system.

Dynamic Contour Detection

The Dynamic Contour Detection solution does not require any programming and moves your production automation to the next level.

OptiMove axis control: powerful and easy to program

This versatile and user friendly unit can be used for the control and programming of all Gema reciprocators and axis.

MagicControl 4.0: The pioneering interface for Smart Factory Automation

The system control ensures intelligent networking for all application components providing greater efficiency and manageability to the process.