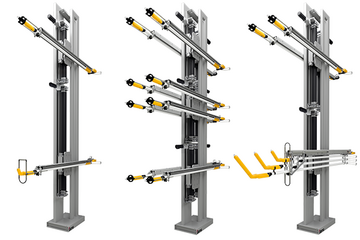

Main Features Overview

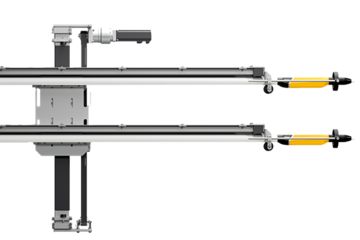

Precise gun positioning

The ZA17 modules move the coating guns either into a variable fixed position or oscillate over a surface, which enables very precise coating of complex parts and inclined beams.

Tailor the axis to your needs

Several different and independently operating axis modules can be combined to meet the coating requirements of complex components.

Designed for smooth operation

The ZA17 is equipped with an advanced synchronized motor for highest efficiency during continuous operation.

Easy service and great reliability

The ZA modules require only minimum maintenance that can be completed easily and quickly.

Space-saving design

Reduction of the booth footprint through the combination of multiple axes into one unit.

Increased automation

Automatic coating and increased coverage of angled contours through precise positioning and continuous adjustment of fixed guns.

© 2025 by Gema Switzerland Gmbh - All rights reserved

| General Conditions of Sales | Conditions of Purchase | Legal Notice | Privacy Policy

design by easy graphics ag